How We Support the Automotive Industry

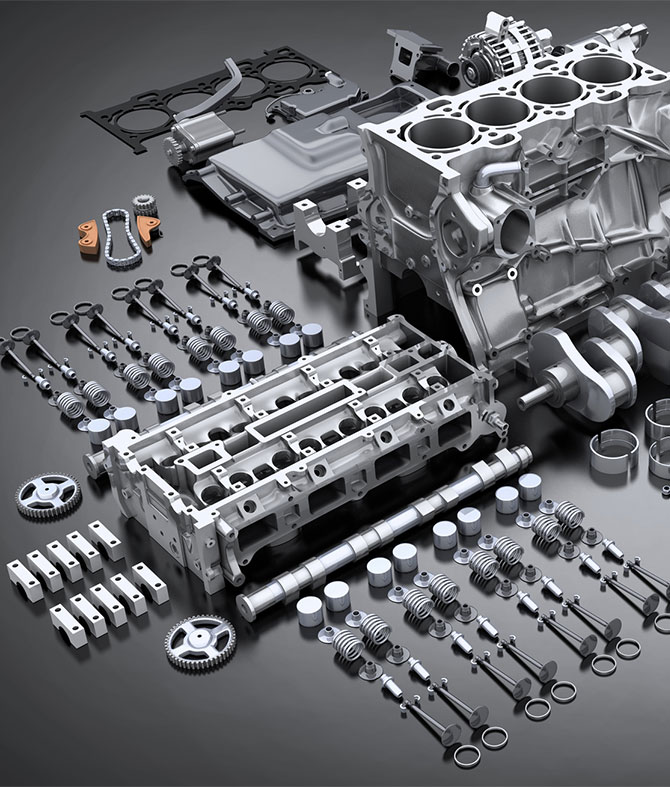

Camshafts

Our custom camshafts are uniquely created and built for peak performance and efficiency. By utilizing skilled craftsmanship and state-of-the-art techniques like 5 axis machining, we craft automotive camshafts that provide the power and reliability you need.

Cam Cores

We are your go-to source for custom cam cores, which form the foundation for any high-performance camshaft. Using Swiss turning and custom CNC grinds, we create cam cores that keep your engine running smoothly and efficiently. If you’re after big bearing cams or need alternative firing orders, our cam cores are built to take your engine to the next level.

Custom Machining

Our custom machining services are designed to meet your precise needs. We offer everything from cylinder block machining to billet block machining, ensuring every part is crafted to your exact specifications. Whether it’s finish machining, rough machining, or block machining, we use 5-axis machining and 4-axis machining for precision and accuracy. This combination allows us to create complex parts with tight tolerances for optimal engine performance.

Industry Expertise

LSM Systems Engineering has become a trusted provider of performance camshafts for enthusiasts across the nation. From hot honing to custom billet block solutions, our expertise in billet aluminum block machining is unmatched.

Our Expertise

Learn more about what we do at LSM and our areas of expertise.

Automotive Industry FAQs

A performance camshaft optimizes engine power, efficiency, and responsiveness. It works by adjusting the timing and movement of the engine’s valves, improving the intake and exhaust processes. This boosts overall engine performance. At LSM Systems Engineering, we custom-manufacture camshafts tailored to your engine’s exact needs.

A billet engine block is made from solid metal, usually billet aluminum, which provides greater strength and durability than traditional cast blocks. This allows the engine to handle more horsepower and withstand the demands of high-stress applications like racing or heavy machinery. We offer both custom billet block and billet block machining services to create optimal performance.

Rough machining removes the bulk of the material in the early stages, while finish machining refines the part to tight tolerances for precision. At LSM Systems Engineering, we use both processes, along with block machining, to guarantee your parts meet the highest quality standards.

Yes! We specialize in designing custom camshafts for any engine type. Whether you need a custom billet block, big bearing camshaft, or alternative fire orders, our team can craft a camshaft that matches your engine’s performance needs perfectly.

Nicasil liners are ceramic coatings that boost the wear resistance of engine parts, reducing friction and extending the lifespan of components like cylinders and pistons. These liners are ideal for high-performance engines, ensuring smoother operation and enhanced durability.

Valvesprings are essential components in the valvetrain system, controlling the movement of the engine’s intake and exhaust valves. At LSM Systems Engineering, are a valve spring manufacturer who customizes all of our pieces to maintain optimal valve timing, all to help make sure that your engine performs at its best throughout its life.

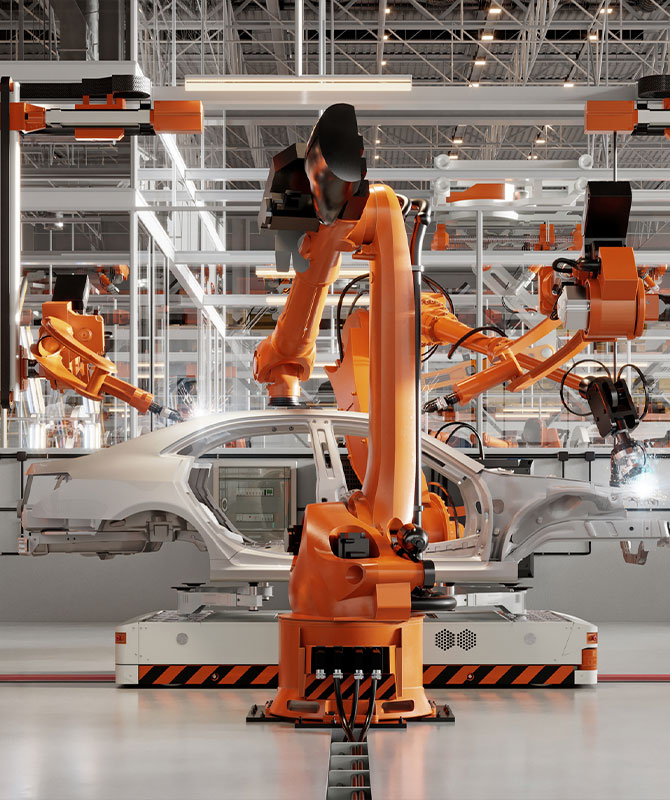

Ready to Boost Your Engine’s Performance with LSM?

At LSM Systems Engineering, we’re committed to providing top-tier custom camshafts, billet engine blocks, and machined auto parts that elevate engine performance. Our custom CNC grinds and other precision services are designed to meet your unique requirements, whether you’re building for racing or high-performance street applications.

Reach out to our team of experts today to discuss your needs and get started on your next project.